Material

Material

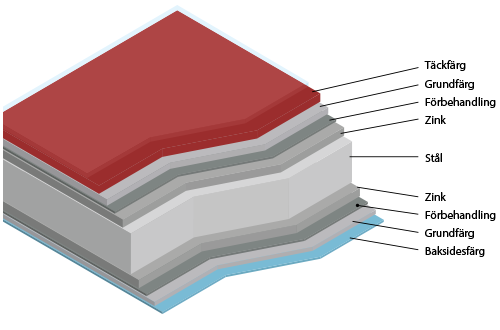

GreenCoat Pro BT®

GreenCoat® products have a bio-based paint coating. All our products comply with the guidelines in REACH. These benefits mean reduced environmental impact.

Colorchart >>

Download brochure for more information >>

Greencoat's structure

Med GreenCoat® får man system i ett helhetstänkande där takhuvar, ytterväggs-galler, byggplåt, vattenavrinning och garnering åldras lika och genom tiden överensstämmer i kulörer.

GreenCoat® color coated steel products comply

with the following provisions:

- REACH regulations

- CLP (1272/2008/EG)

- SundaHus

- BASTA (2017:A1)

- Byggvarubedömningen (BVB, 2013)

- Building product declarations (Association for Building Product Declarations,

BPD 3, 2007).

Tests

- EN 13523-1:2009

- EN 10169 + A1

Source: SSAB

Other materials

Galvanized

Galvanized

The plate consists of a steel core that is metallized by hot-dip galvanizing. Z275, corrosivity class C3.

Aluzinc

Aluzinc

Another method of metallizing sheet steel than hot-dip galvanizing is to coat the sheet with a mixture of zinc, aluminum and silicon. The coating has a greater resistance to general corrosion than a pure zinc layer can achieve. Therefore, the aluzinc sheet is also used without painting treatment. AZ185, corrosivity class C4.

Stainless steel

Stainless steel

The properties of stainless steels are mainly determined by the steel's structure and alloying additions. EN 1.4301 (SS 2333) Corrosivity class C5.

Acid-resistant stainless steel

Acid-resistant stainless steel

The acid-resistant steel sheet we use is EN 1.4404 (SS 2348).

Copper

Copper

Copper is a classic and exclusive material. Thanks to its softness and malleability, the material has been used throughout the ages for prominent buildings, often in combination with complicated decorations. Nowadays, copper sheet's areas of use have broadened, among other things thanks to the material's good corrosion properties.

Aluminum

Aluminum

The corrosion resistance of aluminum is very good. When aluminum is exposed to air, a well-adherent and hard oxide layer spontaneously forms. Despite the good corrosion resistance, it is often the case that, for aesthetic reasons, the aluminum sheet is painted. Aluminum should not be exposed to lime, plaster, concrete or similar alkaline products.

Rheinzinc/Titanzinc

Rheinzinc/Titanzinc

Titanium zinc sheet has a surface with a characteristic shiny metallic surface. Zinc exposed to the outdoors acquires a beautiful grey-blue patina over time, at different rates depending on the slope and direction of the weather. The material has good corrosion resistance and is very malleable in the hands of a skilled professional. Also available in pre-patinated version.

Zinc magnesium

Zinc magnesium

Metal coating for steel with 3% magnesium. The magnesium content in the alloy increases corrosion resistance compared to other anti-rust treatments. Zinc magnesium provides very good protection in environments that are strongly alkaline or contain chloride and ammonia. ZM310, corrosivity class C5. Tested and approved by SP for use in marine environments up to corrosivity class C5 with a warranty period of 20 years.